Stainless Steel Coil

403 Stainless Steel Coil

403 Stainless Steel Coil Description403 stainless steel has excellent mechanical properties, including high hardness, high strength and high wear resistance. It is commonly used in the manufacture of high hardness tools, cutting tools, bearings and valves and other industrial parts, especially in ap

- Factory area 20000 square meters.

- Support specification customization.

- Strict quality control, ISO certification.

- Abide by the contract and deliver on time.

- After-sales team gives you the best service.

403 Stainless Steel Coil Description

403 stainless steel has excellent mechanical properties, including high hardness, high strength and high wear resistance. It is commonly used in the manufacture of high hardness tools, cutting tools, bearings and valves and other industrial parts, especially in applications requiring corrosion resistance and wear resistance. In addition, 403 stainless steel can also be used in food processing equipment, chemical equipment, medical equipment and other fields to meet the requirements of corrosion resistance and mechanical properties.

Product Parameters

Product Name 403 Stainless Steel Coil Type Steel Coil Thickness 2.5mm-10.0mm Length 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc. Width 610mm-2000mm Standard ASTM, AISI, JIS, GB, DIN, EN, etc. Surface BA, 2B, NO.1, NO.4, 4K, HL, 8K, etc. Scope of Application Widely used in high temperature and electrical industry, medical equipment construction, chemical, food industry, agriculture and ship parts, food and beverage packaging, Kitchen supplies, trains, airplanes, conveyor belts, vehicles, bolts, nuts, springs and screens, etc. Certificate ISO, SGS, BV, etc. Production Technology Hot Rolling, Cold Rolling Edge Processing Edging, Trimming

Chemical Composition

C Si Mn Cr Ni S P ≤ 0.15 ≤ 0.5 ≤1.0 11.5~13.0 ≥ 0.6 ≤ 0.03 ≤ 0.04

Mechanical Properties

Tensile Strength Kb (MPa) Yield Strength σ0.2 (MPa) Elongation D5 (%) Hardness ≥485 ≥290 ≥25 ≤ 98HRB

Physical Performance

Density(g/cm³) Modulus of Elasticity(Gpa) Coefficient of Thermal Expansion(10-6/°C) Coefficient of Thermal Conductivity(W/m*K) Resistivity(10-6 Ω.m) 7.80 190 9.9 21.5 740

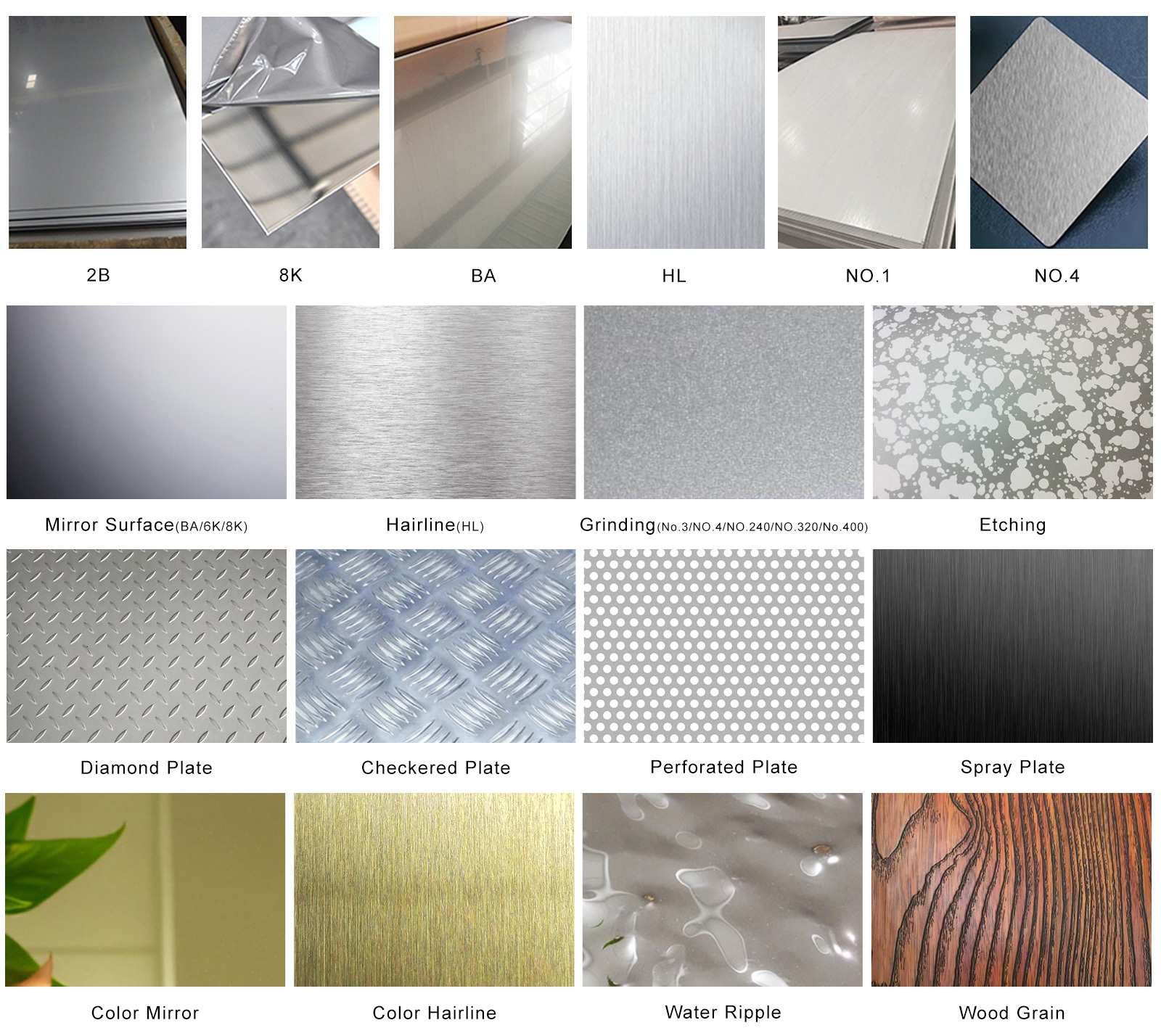

Surface Selection

Greatest product everGalvanized coils are our top choice for durability and consistency. The zinc layer uniformity saves us time in post-processing, and your team’s technical support is always helpful. |

|

Mahan Selon |

Greatest product everWe have been purchasing yulun galvanized steel coils for the quality has consistently exceeded our expectations. The coating uniformity, corrosion resistance, and surface finish meet our strict standards, making them ideal for construction. |

Mark Doe