Stainless Steel Plate

316 Stainless Steel Plate

316 Stainless Steel Plate DescriptionGrade 316 stainless steel is an austenitic form of stainless steel with a molybdenum content of 2-3%. The addition of molybdenum makes the metal more resistant to pitting and corrosion and improves its resistance to exposure to high temperatures. This grade of st

- Factory area 20000 square meters.

- Support specification customization.

- Strict quality control, ISO certification.

- Abide by the contract and deliver on time.

- After-sales team gives you the best service.

316 Stainless Steel Plate Description

Grade 316 stainless steel is an austenitic form of stainless steel with a molybdenum content of 2-3%. The addition of molybdenum makes the metal more resistant to pitting and corrosion and improves its resistance to exposure to high temperatures. This grade of stainless steel is particularly effective when used in acidic environments. With this metal, corrosion caused by acetic acid, hydrochloric acid and other forms of acid can be prevented.

Product Parameters

Product Name 316 Stainless Steel Plate Type Plate Thickness 0.3mm-200mm Length 2000mm, 2438mm, 3000mm, 5800mm, 6000mm, 12000mm, etc. Width 40mm-600mm, 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc. Standard ASTM, AISI, JIS, GB, DIN, EN, etc. Surface BA, 2B, NO.1, NO.4, 4K, HL, 8K, etc. Scope of Application Widely used in high temperature and electrical industry, medical equipment construction, chemical, food industry, agriculture and ship parts, food and beverage packaging, Kitchen supplies, trains, airplanes, conveyor belts, vehicles, bolts, nuts, springs and screens, etc. Certificate ISO, SGS, BV, etc. Production Technology Hot Rolling, Cold Rolling Edge Processing Edging, Trimming

Chemical Composition

C Si Mn Cr Ni S P Mo ≤ 0.03 ≤ 0.75 ≤ 2.0 16.0~18.0 10.0~14.0 ≤ 0.03 ≤ 0.045 2.0~3.0

Mechanical Properties

Tensile Strength Kb (MPa) Yield Strength σ0.2 (MPa) Elongation D5 (%) Hardness ≥480 ≥177 ≥ 40 ≤ 187HB;≤ 90HRB;≤ 200HV

Physical Performance

Density(g/cm³) Modulus of Elasticity(Gpa) Coefficient of Thermal Expansion(10-6/°C) Coefficient of Thermal Conductivity(W/m*K) Resistivity(ΜΩ. cm) 7.99 193 16.0 16.2 74

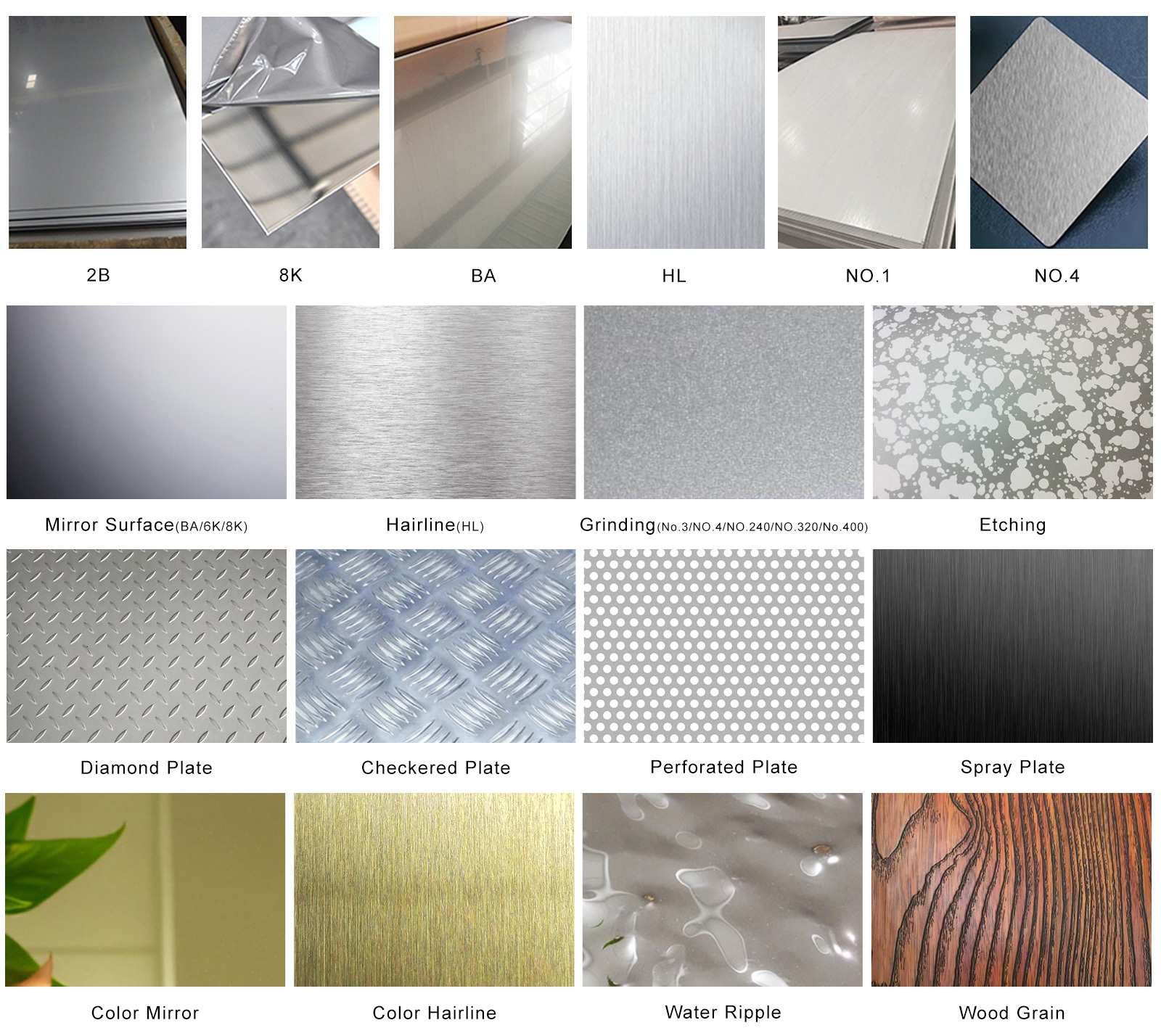

Surface Selection

Industrial tanks, chemical industry equipment, etc., thicker by the mm-10.0mm of 3.0. Uses that do not require a surface gloss Used for deep drawing processing, such as automobile components, water pipes, etc. General materials, deep drawing materials Such as tableware, building materials, etc. After surface treatment to improve mechanical properties, almost all applications are satisfied. Used for building interior and exterior decoration materials, electrical products and kitchen equipment. Used for baths, building interior and exterior decoration materials, electrical products, kitchen equipment and food equipment. Used for bathroom, building interior and exterior decoration materials, electrical products, kitchen equipment and food equipment.Name Surface Features Use Original Surface NO.1 Silver white Matte Nlunt Surface 2D Slightly shiny silvery white Fog Surface 2B Silver white with better gloss and flatness than 2D surface 0.39 micron roughness Frosted Surface NO.3 Has a good gloss, with discontinuous rough Frosted Surface NO.4 Has a better gloss, with discontinuous rough, stripes than NO. 3 fine Frosted Surface NO.240 Has a better gloss, with discontinuous rough, stripes than NO. 4 fine Frosted Surface NO.320 Has a good gloss, with discontinuous rough Building Materials, Kitchenware Frosted Surface NO.400 Has a good gloss, with discontinuous rough Building materials, kitchen utensils, food equipment, etc. Brushed Surface HL Silver gray with hairline stripes on the 2D or 2B product with the appropriate particle size abrasive material polished to make the surface continuous grinding pattern Mainly used in architectural decoration, elevators, building doors, panels, etc. Bright Surface BA Excellent surface gloss with high reflectivity Used for home appliances, mirrors, kitchen equipment, decorative materials, etc. Mirror 6K Not much worse than a mirror. Mirror, trim panel Mirror 8K Like a mirror. Mirror, trim panel

Greatest product everGalvanized coils are our top choice for durability and consistency. The zinc layer uniformity saves us time in post-processing, and your team’s technical support is always helpful. |

|

Mahan Selon |

Greatest product everWe have been purchasing yulun galvanized steel coils for the quality has consistently exceeded our expectations. The coating uniformity, corrosion resistance, and surface finish meet our strict standards, making them ideal for construction. |

Mark Doe