Steel Rebar

BS4449 Steel Reinforcement Rebar

BS4449 Steel Reinforcement Rebar DescriptionBS4449 is yet another deformed steel bar standard. It is also differentiated as per European standards. When it comes to manufacturing, the steel bars falling in this standard are also hot rolled, which means that they are also used for general purposes, i

- Factory area 20000 square meters.

- Support specification customization.

- Strict quality control, ISO certification.

- Abide by the contract and deliver on time.

- After-sales team gives you the best service.

BS4449 Steel Reinforcement Rebar Description

BS4449 is yet another deformed steel bar standard. It is also differentiated as per European standards. When it comes to manufacturing, the steel bars falling in this standard are also hot rolled, which means that they are also used for general purposes, i.e. in common construction projects. These deformed bars are also available between 12 mm to 30 mm diameter size. And the common lengths that they are available in are 9 m and 12 m. Though, it might vary highly.

BS 4449:97 British Rebar Specifications Rated

DiameterNominal Cross Section Area Weight EN To The Ribs (mm) Longitudinal Ribs (mm) Pitch / Step

mmRibs Tip Distance

mmKg / m

Tolerance

%

Height Width Height Width mm m㎡ min. max. min. max. min. max. min. max. min. max. min. max. 6 28.3 0.222 ± 9 0.3 0.6 0.48 0.72 0.3 0.84 0.48 1.2 3,.0 4.8 1.5 2.3 8 50.3 0.395 ± 6.5 0.4 0.8 0.64 0.96 0.4 0.84 0.64 1.6 4.0 6.4 2.0 3.1 10 78.5 0.616 0.5 1.0 0.8 1.2 0.5 0.84 0.8 2.0 5.0 8.0 2.5 3.9 12 113.1 0.888 ± 4.5 0.6 1.2 0.96 1.44 0.6 0.84 0.96 2.4 6.0 9.6 3.0 4.7 16 201.1 1.579 0.8 1.6 1.28 1.92 0.8 0.84 1.28 3.2 8.0 12.8 4.0 6.2 20 314.2 2.466 1.0 2.0 1.6 2.4 1.0 0.84 1.6 4.0 10.0 16.0 5.0 7.8 25 490.9 3.854 1.25 2.5 2.0 3.0 1.25 0.84 2.0 5.0 12.5 20.0 6.2 9.8 32 804.2 6.313 1.60 3.2 2.56 3.84 1.60 0.84 2.56 6.4 16.0 25.6 8.0 12.5 40 1256.6 9.864 2.0 4.0 3.2 4.8 2.0 0.84 3.2 8.0 20.0 32.0 10.0 15.7 50 1963.5 15.413 2.5 5.0 4.0 6.0 2.5 0.84 4.0 10.0 25.0 40.0 12.5 19.6

BS 4449:97 Steel Rebar Mechanical Properties Quality

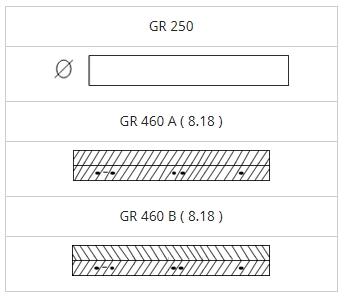

Akma N / mm2< Akma / Pull Rate N/mm2 Elongation Elasticity Total max. % AGT min. min. min. min. GR 250 250 Akma x 1.15 22 – GR 460 A 460 Akma x 1.05 12 2.5 GR 460 B 460 Akma x 1.08 14 5

BS 4449:97 Steel Rebar Chemical Properties Element GR 250 % max. GR 460 A / B % max. Ribs and Marking Method Casting Product Casting Product

C 0.25 0.27 0.25 0.27 P 0.060 0.065 0.050 0.055 S 0.060 0.065 0.050 0.055 N 0.012 0.013 0.012 0.013 CE 0.42 0.45 0.51 0.54 Mn Cr+Mo+V Ni+Cu CE = C + ————- + ——————- + —————– 6 5 15

Scope of Application

Widely used in houses, bridges, roads, especially railways and other civil engineering.

Greatest product everGalvanized coils are our top choice for durability and consistency. The zinc layer uniformity saves us time in post-processing, and your team’s technical support is always helpful. |

|

Mahan Selon |

Greatest product everWe have been purchasing yulun galvanized steel coils for the quality has consistently exceeded our expectations. The coating uniformity, corrosion resistance, and surface finish meet our strict standards, making them ideal for construction. |

Mark Doe